EBSD analysis of Al subgrains in a tungsten SEM

Summary:

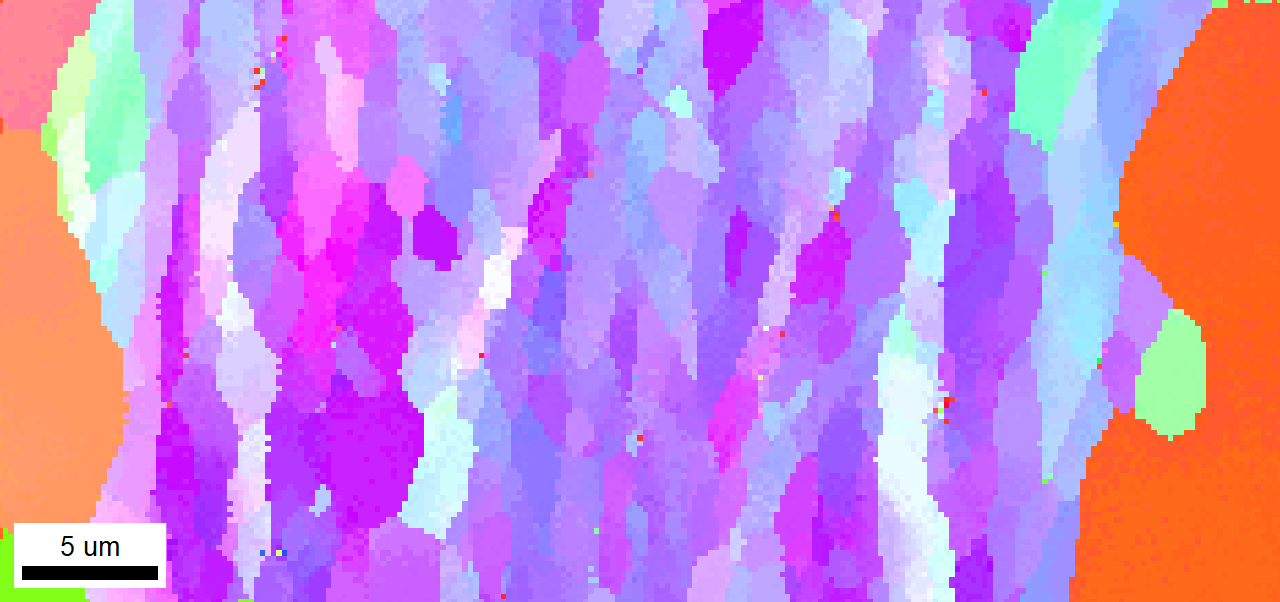

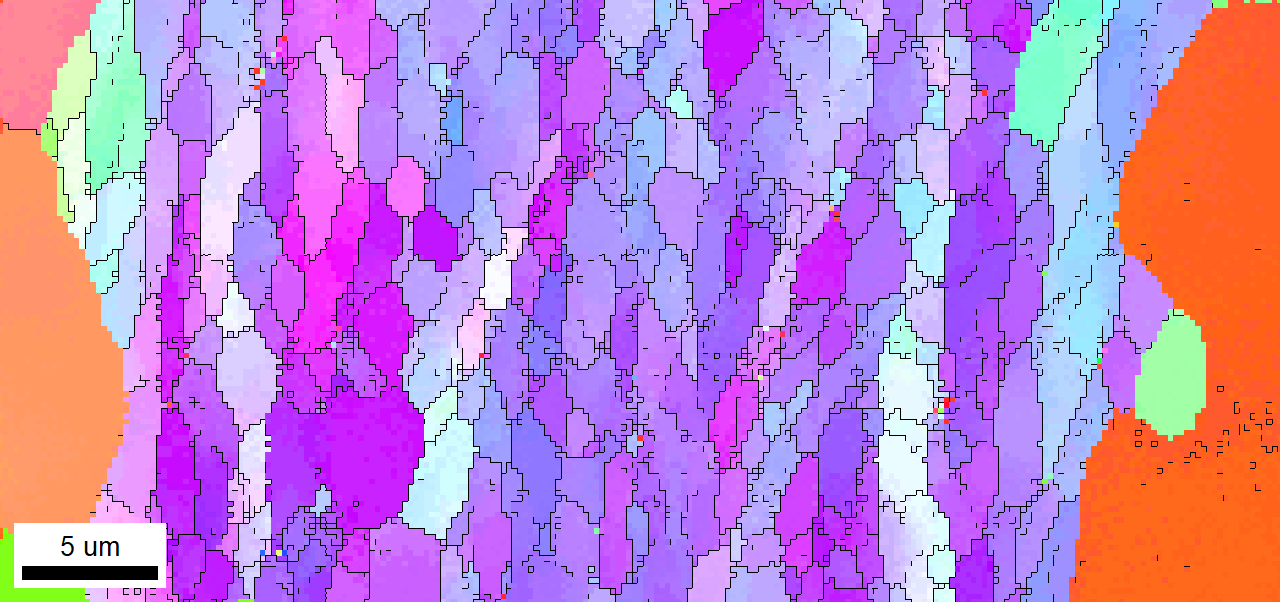

- Dictionary Idexing (DI) was applied to map the subgrain structure in super pure aluminium (99.99%) by the use of a NICE detector attached to a WSEM. The super pure aluminium specimen was 90% cold rolled before a heat treatment of 6 s at 400°C.

Details:

After this thermomechanical treatment the microstructure consists of bands parallel to the rolling direction. Some of the bands consisted of subgrains while other bands showed fully recrystallized grains. The EBSD analysis was performed in a JEOL JSM-IT100 WSEM equipped with a NORDIF In-Chamber EBSD (NICE) detector. The SEM settings were: acc. voltage 20kV, tilt angle 70°, working distance 19 mm, probe current 10 nA. The EBSD settings were: pattern resolution 60x60, frame rate 150 patterns/s, step size 0.2μm, area of interest 22.2 x 47 μm2, totally 26,085 patterns, 3x on-line averaging. The patterns were acquired and streamed to HDD by use of the NORDIF N3 acquisition software. The pattern indexing was executed off-line by DI + refinement by kikuchipy. Before indexing the signal-to-noise ratio in the patterns was improved by an off-line averaging process in kikuchipy. The Figure shows an Inverse Pole Figure (IPF-Z) map generated by DI + refinement. The misorientation between neighbouring orientations in the dictionary was 2°. The EBSD pattern acquisition from a low atomic number Al-specimen was performed on a WSEM with unfavorable settings like long working distance (19 mm) and a high probe current (10 nA). Even under such conditions EBSD mapping of subgrains is working very well when the indexing is performed by off-line DI + refinement.